Main Advantages of Nylon Union for flexible pipe

A nylon flexible Nylon Union for flexible pipe is a lightweight, durable, and versatile conduit widely used in industries such as automotive, machinery, and electronics. Made from high-quality nylon (PA), these hoses provide strong protection for cables, air lines, and fluids. They combine flexibility, toughness, and resistance to wear—making them a preferred choice for both industrial and everyday applications.

1. Lightweight but Strong

Nylon hoses are much lighter than metal or rubber alternatives, reducing system weight and improving efficiency. Despite being light, they offer impressive mechanical strength and can handle high pressure without deforming or breaking.

2. Excellent Flexibility

One of the biggest advantages of nylon flexible hoses is their superior flexibility. They can bend easily without cracking, making them ideal for compact or curved installations. This flexibility allows smooth movement in dynamic systems such as machinery or vehicles.

3. High Wear and Impact Resistance

Nylon has excellent abrasion resistance, which protects the hose from friction and external impact. This makes nylon hoses especially suitable for environments with frequent movement or vibration, such as factory automation systems.

4. Corrosion and Chemical Resistance

Unlike metal pipes, nylon flexible hoses resist corrosion, oil, and most chemicals. They remain stable even when exposed to fuel, lubricants, or solvents, ensuring a long service life in harsh environments.

5. Wide Temperature Range

Nylon hoses can operate in both high and low temperatures without losing strength or flexibility. This stability makes them reliable in outdoor, automotive, or high-heat conditions.

6. Easy Installation

Nylon flexible hoses are easy to cut, connect, and install. They work well with various fittings and cable glands, saving time and labor costs. Their smooth inner wall also allows fluids or cables to pass through easily without damage.

7. Cost-Effective and Long-Lasting

Compared with metal hoses, nylon options are more affordable while still offering excellent performance. Their long lifespan and minimal maintenance needs make them an economical choice for many industries.

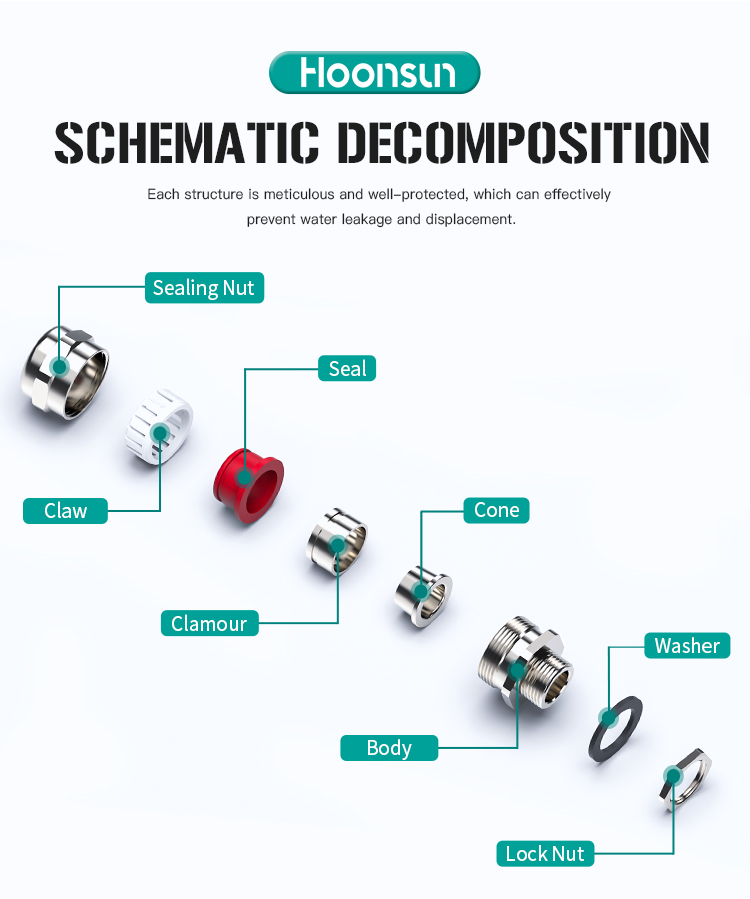

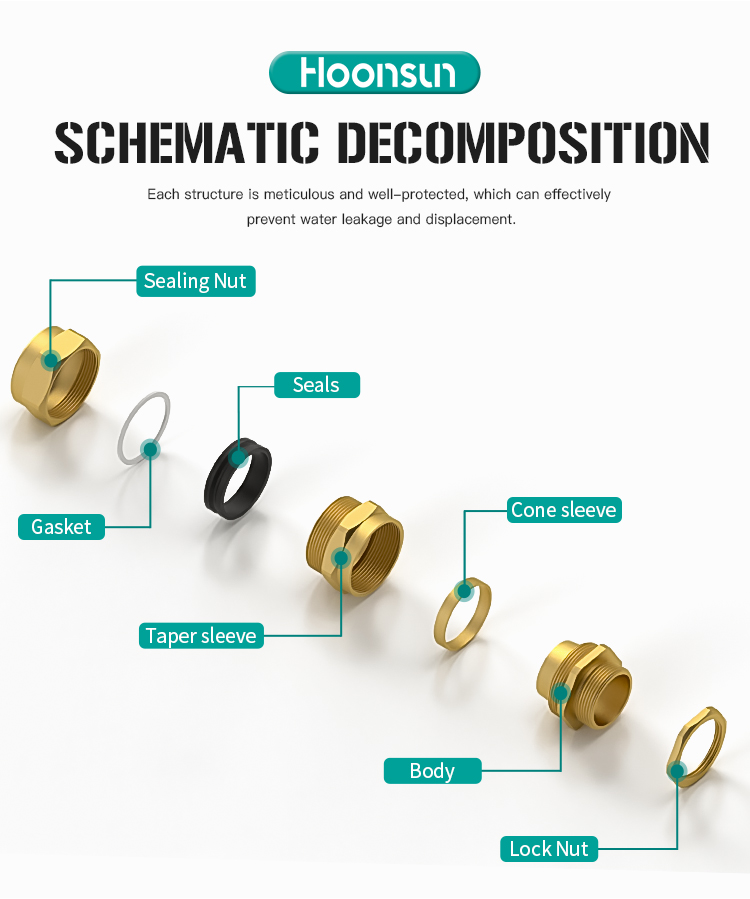

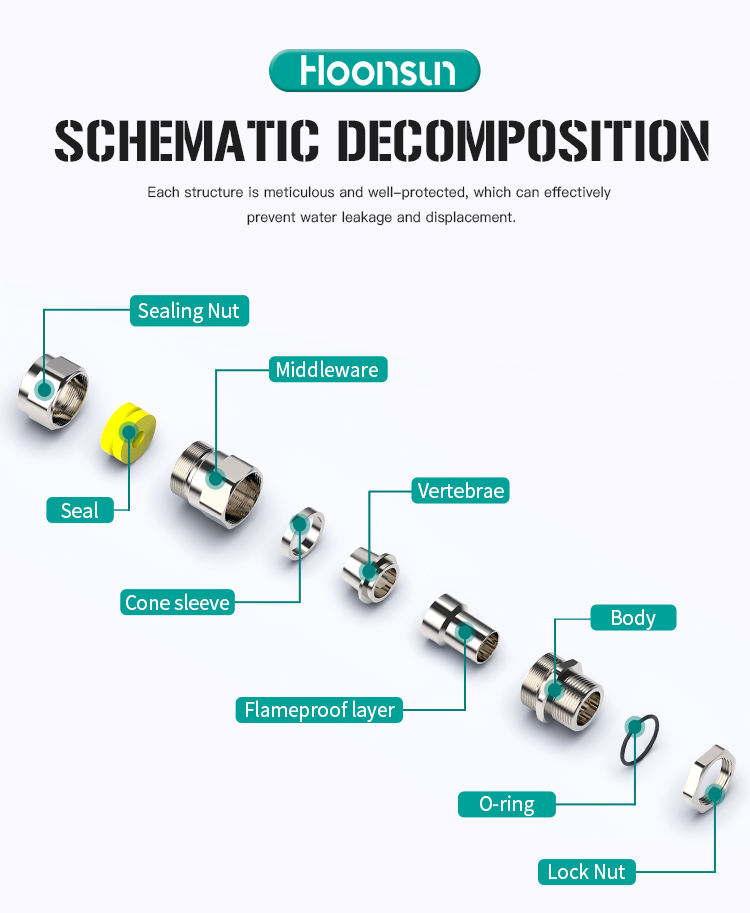

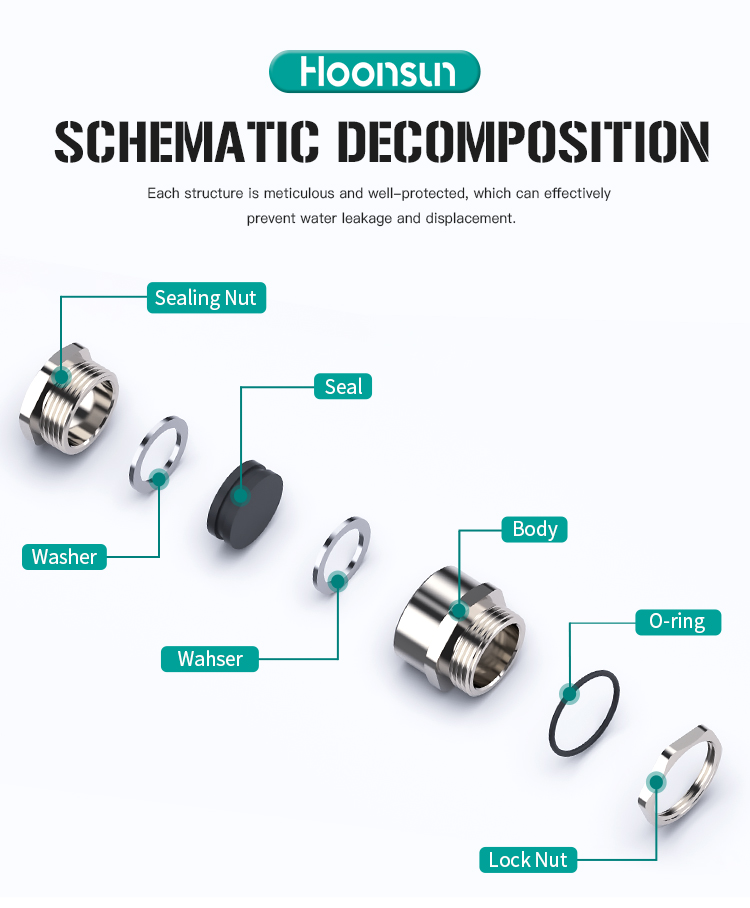

Quick-plug efficient connection: Adopts one-click quick-plug/snap structure, enabling fast docking with hoses without tools. Easy installation and disassembly greatly improve wiring or maintenance efficiency, suitable for batch operation scenarios.

Nylon material advantages: Made of high-quality nylon, lightweight, cost-effective and wear-resistant. Not easy to age or deform, with certain toughness, it adapts to the flexible characteristics of hoses and meets the needs of indoor and outdoor general environments.

Reliable sealing protection: Built-in sealing ring design, achieving IP65 sealing performance after connecting with hoses. Dustproof, waterproof and resistant to mild oil stains, it effectively prevents external impurities from entering and leakage at the connection to ensure connection stability.

Multi-specification adaptation: Compact structure, compatible with hoses and cables of various inner diameter specifications. Wide adaptation range meets the hose wiring needs of different equipment, balancing practicality and versatility.