The global cable gland market is experiencing significant growth, driven by advances in power infrastructure, the booming renewable energy sector, industrial automation, and the rapid expansion of electric vehicle (EV) infrastructure. As industries around the world continue to adopt more advanced technologies and sustainable solutions, demand for reliable, high-performance cable glands—critical components for electrical connections—is steadily increasing.

In this blog, we will explore the growth prospects of the cable gland market and delve into the key opportunities and challenges facing the industry.

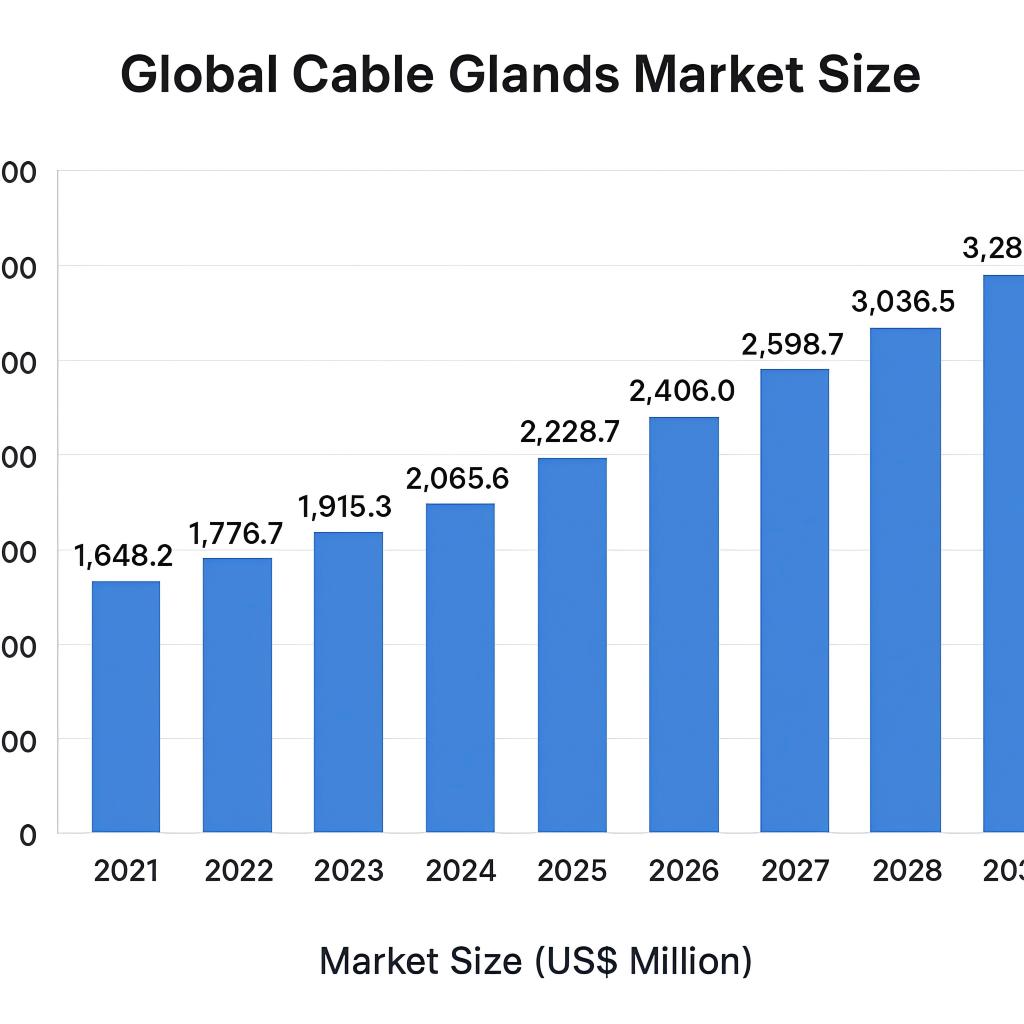

Global Cable Glands Market Growth

The global cable connector market reached US$1.6482 billion in 2021. This growth is driven by factors such as urbanisation, renewable energy development, and the adoption of electric vehicles. So, what exactly is driving this growth?

Power Infrastructure Upgrades

With the ongoing modernisation of power grids—especially the push for smart grids—there is a heightened demand for high- and ultra-high-voltage cable glands. The shift towards smart grids, which use advanced digital technology to improve energy efficiency, means that more reliable and specialized connectors are necessary.

Additionally, the rapid expansion of urban areas has led to increased construction of subways, airports, and industrial parks. These large-scale projects require medium- and low-voltage cable glands to ensure secure and durable electrical connections.

Renewable Energy Boom

As the world moves toward renewable energy sources, especially wind and solar power, the need for robust cable glands is escalating. Offshore wind farms, which require connectors that are waterproof, corrosion-resistant, and able to handle high-voltage connections, are a prime example of this demand. Similarly, energy storage systems and microgrids are emerging trends that further increase the need for high-reliability connectors.

Electric Vehicles and Charging Infrastructure

The rise in electric vehicle sales is directly contributing to the growth of the cable glands market. EVs demand high-power charging stations, battery pack connections, and motor connections—all of which require specialised cable glands designed to handle higher safety standards, high temperatures, and low contact resistance. Fast-charging technologies, especially DC fast charging, further amplify the need for advanced cable connectors.

Industrial Automation

The trend toward industrial automation and the rise of smart factories is driving demand for high-performance connectors. With automated production lines, robots, and industrial Ethernet networks, industries need dust-proof, vibration-resistant, and quick-connect cable glands to ensure smooth, uninterrupted operations.

Challenges in the Cable Glands Market

While the cable glands market is growing, it faces several challenges that manufacturers need to address: