As renewable energy systems continue to expand in solar, wind, and offshore applications, the reliability of every electrical connection becomes increasingly critical. Cable joints play a vital role in ensuring the safe, stable, and long-term operation of systems.

They protect cables from environmental stresses, maintain the integrity of the casing, and prevent moisture, dust, and mechanical stress from damaging the system. For renewable energy installations exposed to harsh outdoor environments, the correct selection of cable joints directly impacts operational efficiency and the overall lifespan of the system.

When selecting cable joint solutions for renewable energy projects, several key factors must be evaluated to ensure compatibility and reliability. Whether in photovoltaic junction boxes, wind turbine nacelles, or offshore platforms, choosing the right joints ensures robust protection and minimizes maintenance risks.

Enhancing System Reliability Through High-Quality Cable Joint Solutions

Critical Nodes in Electrical Connections

In renewable energy systems, the entire process of energy generation, transmission, and grid connection requires connections via joints. These critical nodes rely on cable joints to ensure the continuity of energy transmission.

Weak Links Determining System Reliability

In numerous renewable energy accident statistics, joints are the most common point of failure. Joint failures account for over 60% of photovoltaic fires, wind power generation failures, and thermal runaway accidents in energy storage systems. Therefore, Hoonsun cable joints can improve the reliability of the entire system.

Ensuring Ease of Maintenance and Cost

High-quality cable joint connectors feature: quick-connect and disconnect structure, low maintenance frequency, online monitoring, and modular replacement. The better the quality of the cable joint connector, the lower the maintenance cost throughout its lifecycle.

What Types Of Cable Glands Are Used In Renewable Energy Systems?

Renewable energy systems operate in a variety of often harsh environments, such as the high UV radiation of solar power plants, the intense vibrations inside wind turbines, and the corrosive atmosphere of offshore facilities.

To ensure stable and reliable electrical connections, each application requires specially designed cable joints to meet specific mechanical, environmental, and safety requirements. Therefore, selecting the appropriate cable joint type is crucial for protecting cables, maintaining enclosure protection levels, and ensuring long-term system reliability.

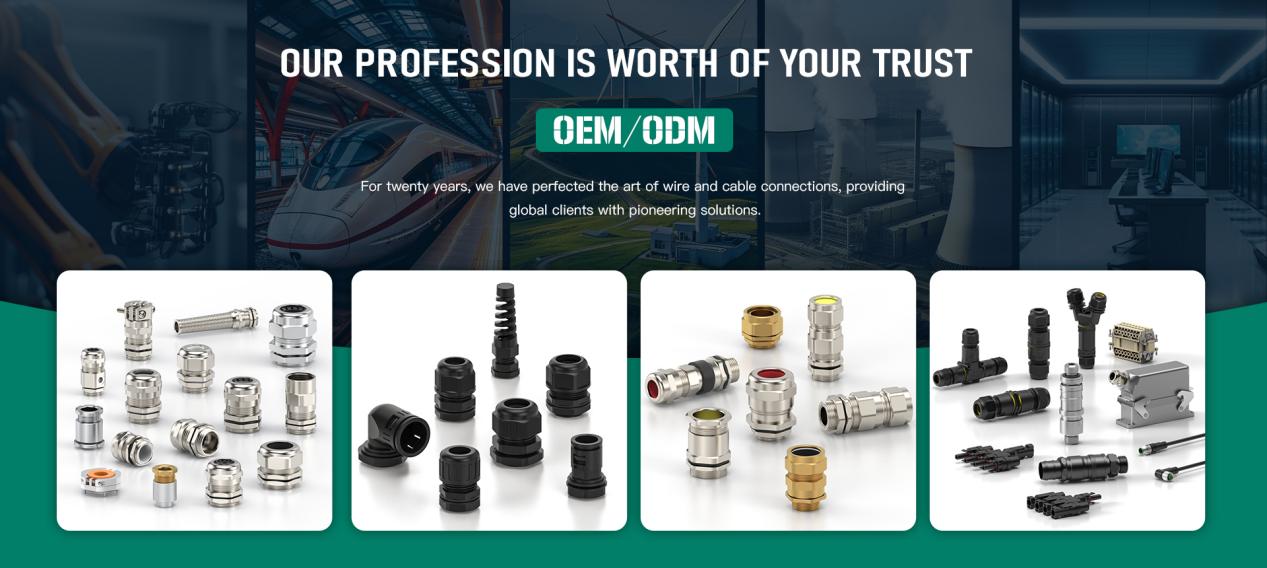

Common cable joint types in the renewable energy sector include metal joints (such as brass cable glands, stainless steel cable glands, and aluminum cable glands), which offer high mechanical strength and corrosion resistance, making them ideal for wind turbine nacelles and offshore platforms.

Plastic and nylon joints provide lightweight, UV-resistant, and cost-effective solutions for solar photovoltaic modules and junction boxes.

For environments requiring reliable sealing, EMC/EMI cable joints help maintain electrical continuity and shield against interference.

Explosion-proof cable joints are essential for energy storage systems or hydrogen facilities with potential ignition risks.

Furthermore, weatherproof and IP68-rated connectors are widely used across all renewable energy sectors to ensure protection against moisture, dust, and thermal cycling.

By matching the type of seal to specific environmental and technical requirements, engineers can significantly improve the performance, safety, and operational efficiency of renewable energy installations.

Why Are Cable Glands Essential In Renewable Energy?

The performance and lifecycle of renewable energy systems depend heavily on electrical reliability.

Cable glands provide: