The Ultimate Guide to Liquid Cooling Connectors

Liquid cooling connectors are precision-engineered fittings that create a secure, leak-proof connection between tubes, hoses, or pipes carrying coolant throughout a system.

Even the smallest leak can compromise an entire cooling circuit, leading to hardware instability or costly component damage. That’s why the primary function of these connectors is to maintain a tight seal, ensuring the coolant remains safely contained while flowing freely through the system.

What is Liquid Cooling Connectors?

High-quality liquid cooling connectors are also designed to minimize flow resistance and turbulence. By allowing coolant to circulate efficiently, they improve heat absorption and dissipation—critical for maintaining optimal thermal performance and extending the lifespan of sensitive components.

Another key advantage is flexibility. These connectors make it easy to disconnect, replace, or upgrade components without the need to disassemble the entire cooling setup, saving both time and effort during maintenance or system modifications.

Next-Generation Liquid Cooling Connectors

HOONSUN, a leading global provider of connectivity solutions, has officially launched its next-generation high-density, ultra-low-leakage liquid cooling connector series.

Engineered to tackle the escalating thermal management challenges in next-generation data centers, AI computing clusters, and high-performance computing (HPC) environments, this new series delivers more efficient, reliable, and easy-to-deploy components that advance the performance of modern liquid cooling infrastructures.

What are The Specifications of Hoonsun Liquid Cooling Connectors?

OCP-Compliant Designs Enhance Compatibility

The new series includes the UQD and UQDB connectors, both of which conform to the Open Compute Project (OCP) Universal Quick Disconnect specifications. The UQD models offer push-pull quick connect functionality, while the UQDB connectors feature blind mate technology with a 1 mm radial tolerance—ideal for server racks and manifold connections in data centers.

Precision Engineering for High Flow and Absolute Reliability

Both series feature a high-performance sealing system crafted from aerospace-grade materials to guarantee leak-free connections under demanding conditions.

A dry-break, bidirectional shut-off valve minimizes fluid loss during disconnection, while stainless steel housings provide exceptional corrosion resistance and ensure long-term durability in the most challenging environments.

Compact Design for Maximum Integration Flexibility

The compact form factor features short overall lengths and small diameters, enabling seamless integration into space-constrained installations.

Available in four standardized OCP sizes (02, 04, 06, 08), each connector type offers inline or right-angle configurations, providing versatile solutions to meet diverse layout requirements.

Flexible Termination Options for Broader Compatibility

Customers can choose between barbed and threaded terminations to meet specific installation requirements.

These connectors are compatible with a wide range of cooling media, including deionized water, ethylene glycol, and propylene glycol.

They operate safely within a pressure range of 0 to 0.6 MPa, with a maximum pressure tolerance of up to 2 MPa, ensuring reliable performance across diverse applications.

Engineered for Datacom and Power Electronics Excellence

With performance surpassing OCP specifications, Hoonsun liquid cooling connectors are purpose-built for high-reliability applications.

In datacom environments, they ensure efficient thermal management for power-intensive servers and networking equipment.

Beyond IT infrastructure, they also meet the stringent demands of electric vehicle charging systems and modular battery energy storage solutions, delivering consistent performance across critical industries.

Conversion Chart

Flow

1 L/min =0.06 m³/h=0.04 ft³/min=0.26 gallon/min

| L/min | m³/h | ft³ 3/min | gallon/min |

| 1 | 0.06 | 0.04 | 0.26 |

| 6 | 0.36 | 0.21 | 1.59 |

| 12 | 0.72 | 0.42 | 3.17 |

| 18 | 1.08 | 0.64 | 4.76 |

| 30 | 1.8 | 1.06 | 7.93 |

| 60 | 3.6 | 2.12 | 15.85 |

| 120 | 7.2 | 4.24 | 31.70 |

Pressure

1 bar =100,000 pa =100 kpa =0.1 Mpa=14.5 psi=750 mmHg=1.02 kgf/cm²

| bar | pa | kpa | Mpa | psi | mmHg | kgf/cm² |

| 0.1 | 1×10⁴ | 10 | 0.01 | 1.45 | 75 | 0.1 |

| 0.5 | 5×10⁴ | 50 | 0.05 | 7 | 375 | 0.51 |

| 1 | 1×105 | 1×10² | 0.1 | 14.5 | 750 | 1.02 |

| 4 | 4×105 | 4×10² | 0.4 | 58 | 3×10³ | 4.08 |

| 8 | 8×105 | 8×10² | 0.8 | 116 | 6×10³ | 8.16 |

| 10 | 1×106 | 1×10³ | 1 | 145 | 7,501 | 10.20 |

| 12 | 1.2×106 | 1.2×10³ | 1.2 | 174 | 9,001 | 12.24 |

| 14 | 1.4×106 | 1.4×10³ | 1.4 | 203 | 10,501 | 14.28 |

| 16 | 1.6×106 | 1.6×10³ | 1.6 | 232 | 12,001 | 16.32 |

| 18 | 1.8×106 | 1.8×10³ | 1.8 | 261 | 13,501 | 18.35 |

| 20 | 2×106 | 2×10³ | 2 | 290 | 15,001 | 20.39 |

What are the Different Types of Liquid Cooling Connectors?

Universal Quick Disconnects (UQD)

Universal Quick Disconnects were developed through cooperative efforts by several major industry players, including Intel. It was a standard solution that transcended brand barriers.

Their greatest strength lies in widespread compatibility: an end user can interchange connectors from different manufacturers with minimal hassle.

UQD Series Coupling

| Application | Data Centre, HPC | |

| Technical Features |

|

|

| Technical data | |

| Nominal diameter | DN03、05、07、10 |

| Body material | 316Lstainless steel |

| Sea material | EPDM, HNBR、 FVMQ, and other seal materials can be chosen |

| Working pressure | 20bar |

| Burst pressure | 80bar |

| Working temperature | -40℃~+120℃ |

| Fluid | Deionised water, purified water, glycol water, propanediol water, fluorinated liquid |

| Others | Please contact us if you need red/blue colored marks |

Blind Mate Couplings

Blind Mate liquid cooling couplers are designed to connect components without relying on precise visual alignment. Think of them as the “easy button” for mating in tight or limited-access spaces.

In data centers, where racks are frequently added, rearranged, or swapped out, these liquid cooling couplers save valuable time and reduce the margin of error.

Unlike standard electronic connectors, which require you to visually align each coupling, blind mate couplings can accommodate slight misalignments while still ensuring a secure seal.

Advanced Features of Hoonsun Liquid Cooling Connector

Hoonsun liquid cooling connector series is meticulously designed, incorporating multiple innovative technologies to meet the most demanding application requirements:

Superior Reliability and Ultra-Low Leakage

Utilizing a patented sealing structure and high-quality materials, it maintains near-zero leakage after thousands of plug-in/plug-out cycles and extreme temperature and pressure testing, significantly enhancing data center operational safety and stability.

High-Flow, Low-Pressure-Drop Design

Optimized internal flow channel design significantly reduces coolant flow resistance, enabling more coolant to be delivered per unit time, thereby removing more heat and directly improving overall cooling system efficiency.

Blind-Mating and High-Density Compatibility

Supporting blind-mating within a certain tolerance range, it simplifies installation and maintenance within server cabinets, making it particularly suitable for GPU clusters. Its compact design supports high-density layouts, helping customers maximize computing power within limited space.

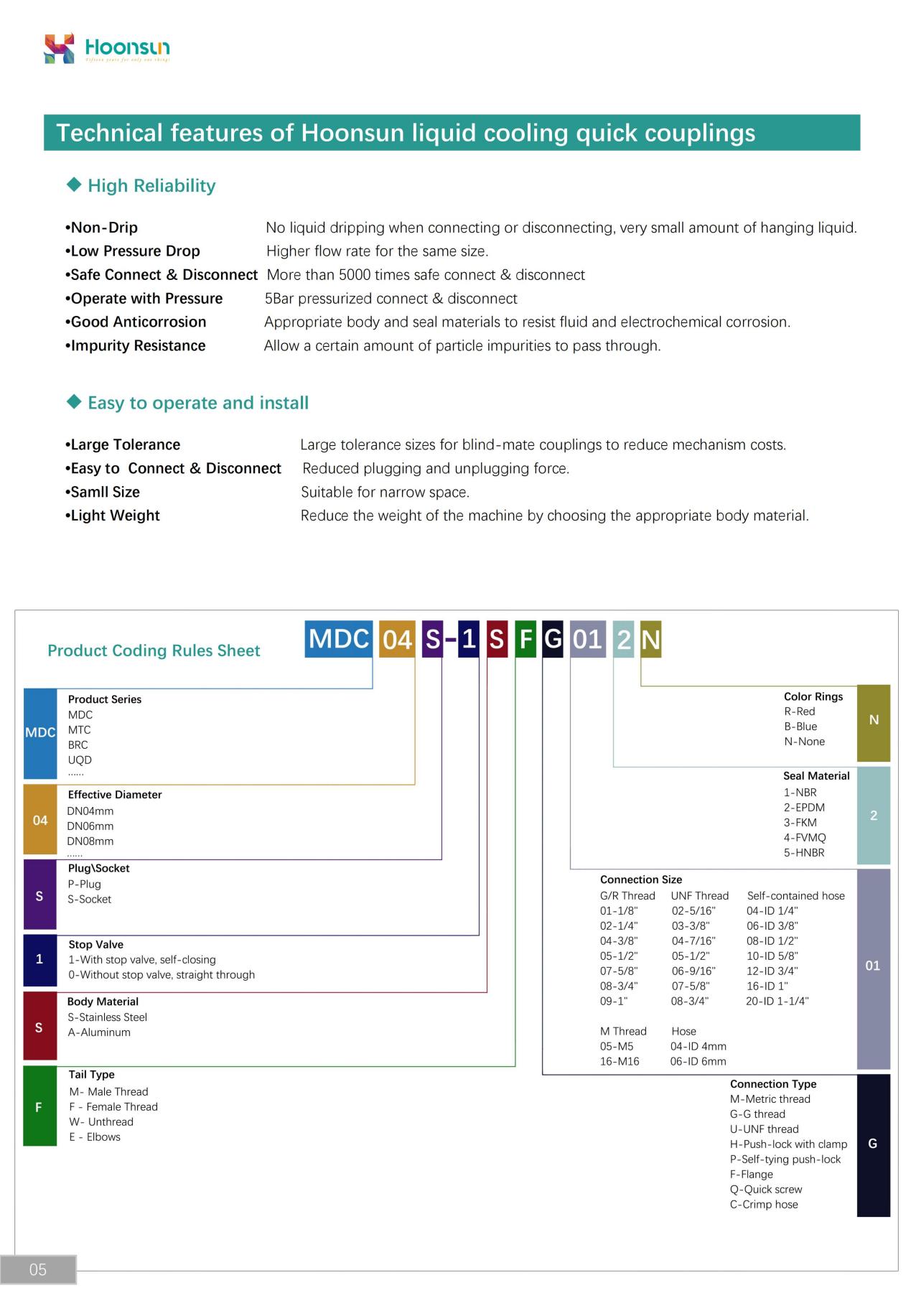

MDC Series Coupling

| Application | Data Centre.HPC, Semiconductor Equipment, Medical Equipment | |

| Technical Features |

|

|

| Description | |

| Nominal diameter | DN04-25 |

| Body material | 316L Stainless Steel.Aluminium Alloy |

| Seal material | EPDM.FKM、FVMQ, and other seal materials can be chosen |

| Working pressure | 20bar |

| Burst pressure | 80bar |

| Working temperature | -40℃-+120℃ |

| Fuid | Deionised water, purified water.glycol water, propanediol water, fluorinated liquid |

| Others | Please contact us if you need red/blue colored marks |

Excellent Electrical Isolation and Corrosion Resistance

Its superior insulation properties resist chemical corrosion from various coolants, ensuring a long service life under harsh operating conditions.

Why Choose Hoonsun’s Liquid Cooling Connector?

By enabling more efficient liquid cooling systems, Hoonsun’s liquid cooling connector solutions help data centers:

- Significantly reduce power usage effectiveness (PUE)—ensuring more energy is used for computing rather than cooling.

- Enable waste heat recovery—facilitating cascading energy utilization and reducing overall environmental impact.

- Support higher computing power density—paving the way for the next generation of AI innovation and advanced scientific research.

HOONSUN BLC Series Liquid Cooling Connector with UL Certification is a high-performance component designed for reliable liquid cooling systems. Engineered from high-temperature and corrosion-resistant materials, this connector ensures stable operation under high pressure and extreme temperatures.

It provides secure and leak-proof connections for transferring coolant, preventing overheating and protecting critical equipment. With excellent sealing performance, pressure resistance, and long-term durability, the BLC series is ideal for various cooling applications.

Key Features

- Efficient Coolant Transfer: Ensures optimal temperature control by circulating water or specialized cooling fluids with high efficiency.

- Leak-Proof Sealing: Advanced sealing technology eliminates leakage risks, enhancing equipment safety and long-term reliability.

- High Pressure & Corrosion Resistance: Built to endure harsh environments and extended operational cycles without performance degradation.

- Versatile Connector Options: Available in quick-connect, threaded, and sliding types to meet diverse system integration needs.

Applications

- Computer Cooling: Ideal for liquid-cooling GPUs, CPUs, and motherboards to achieve superior thermal performance.

- Automotive Systems: Supports efficient cooling for engines and batteries in electric and hybrid vehicles.

- Industrial Equipment: Delivers advanced thermal management for heavy-duty and high-power industrial machinery.

Hoonsun’s next-generation liquid cooling connector series is now available for sample ordering. This series offers a variety of interface specifications and material options to meet diverse customer system design needs.

How to Choose the Right Hoonsun Liquid Cooling Connector?

Construction and Materials

The structural integrity of the connector and its materials is the first line of defense against accidental leaks, corrosion, and chemical breakdown. Incompatible components will degrade quickly, and improper sealing methods can cause dripping or splashing liquids, damaging your expensive hardware.

Common Material Options

These connectors are popular for their lightweight and resistance to a wide range of chemicals. They are often used in tight spaces where weight must be minimized.

Plated Brass

This material is known for its durability and corrosion resistance. The plating adds an extra layer of protection, helping to prevent oxidation.

Stainless Steel

A top choice for industrial or high-temperature environments, it offers excellent corrosion resistance and mechanical strength.

Aluminum

This material is generally lighter and more cost-effective, but may require careful selection of compatible coolants to avoid galvanic corrosion when used with dissimilar metals.

Pro Tip

Always verify that your chosen connector material (such as brass, stainless steel, or high-grade plastic) is compatible with the coolant to avoid corrosion or chemical degradation.

To learn more about this liquid cooling connector and how it can benefit your project, please visit our official website or contact our technical sales team.

How Can We Help You?

Our professional team is ready to provide you with prompt and support.