Product Description

Photovoltaic connectors are electrical connectors specifically used to connect various components in solar power generation systems (such as solar panels, inverters, batteries, etc.). Their main function is to ensure the stability, safety and efficiency of power transmission in photovoltaic systems.

Function

1. Power transmission function

The primary function of photovoltaic connectors is to stably transmit the power generated by solar panels to inverters, batteries or other power system components. They are able to carry higher currents and voltages, and ensure efficient power transmission to avoid power loss.

2. Ensure safety

The photovoltaic system requires stable current and voltage when working. Photovoltaic connectors ensure the safe operation of the system through mechanisms such as firm connection, arc prevention and short circuit prevention.

Many photovoltaic connectors are equipped with anti-reverse connection function to avoid damage caused by incorrect connection of the solar panel.

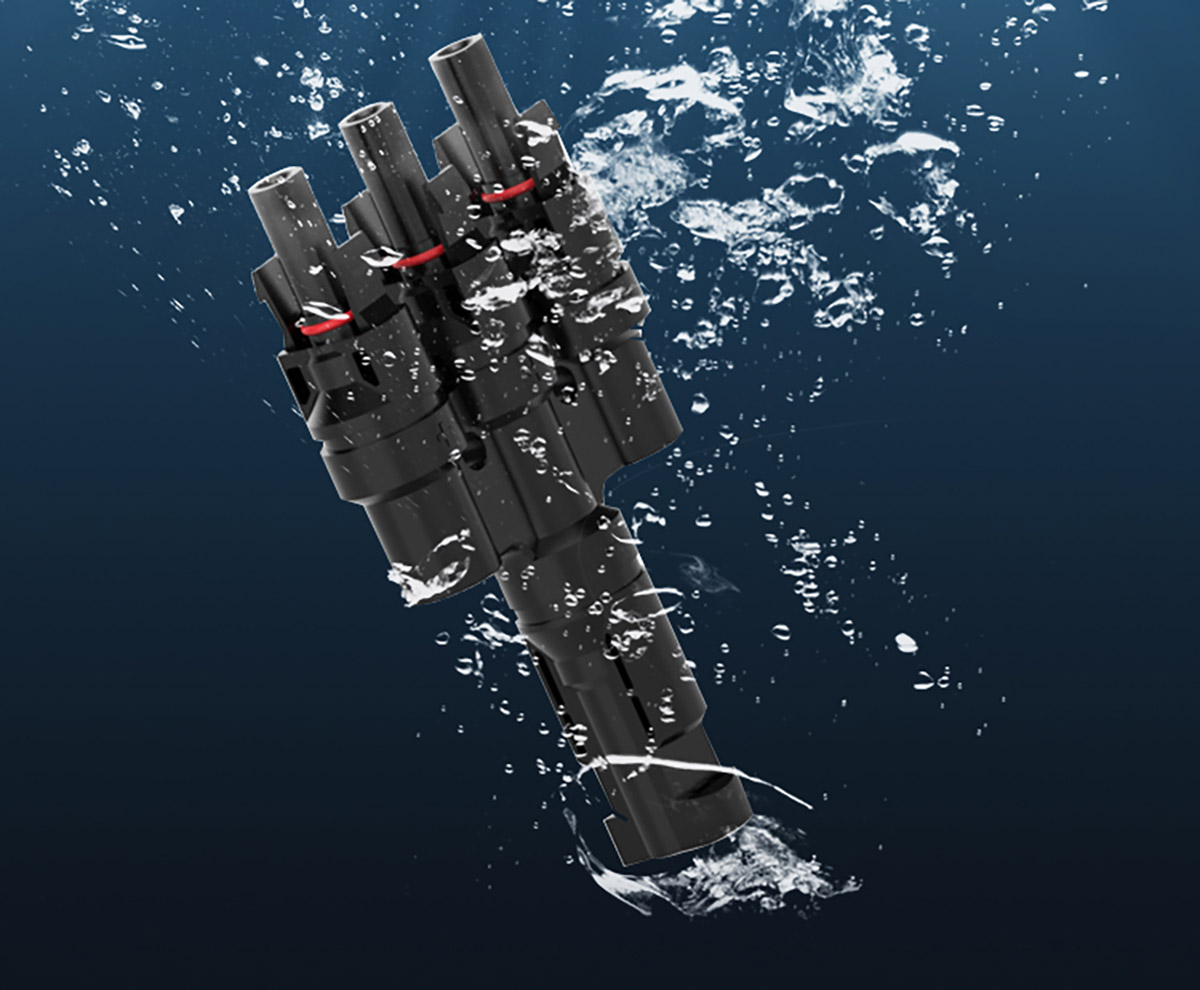

Waterproof and dustproof: Photovoltaic connectors are usually waterproof and dustproof, meet international standards IP67 or IP68, and can be used for a long time in harsh outdoor environments.

3. High voltage and high current carrying capacity

Photovoltaic panels usually operate at high voltages (such as above 60V), and photovoltaic connectors are designed to withstand such high voltages and larger currents in the system. Photovoltaic connectors need to maintain stable electrical contact under these conditions to prevent safety issues such as overheating, damage or fire.

4. Anti-UV and high temperature resistance

Since photovoltaic systems are exposed to sunlight all year round, photovoltaic connectors must be **resistant to ultraviolet rays (UV)**. Materials usually use special plastics (such as PC/PA66) that can effectively resist ultraviolet radiation and prevent aging.

Photovoltaic connectors also need to be able to withstand high temperatures and maintain stability under extreme temperature conditions (from low to high temperature environments).

5. Anti-arc design

When connecting and disconnecting electrical equipment, arcs are easily generated, and photovoltaic connectors are usually designed with anti-arc functions. They can quickly cut off the current and avoid arc damage to the connector itself and other system components.

6. Quick connection and removal

Photovoltaic connectors usually adopt a quick plug-in design to make installation and maintenance easier. Without additional tools, photovoltaic modules and other equipment can be quickly connected and disconnected, greatly improving the efficiency of installation and maintenance.

7. Anti-corrosion

Photovoltaic systems are installed outdoors and exposed to humid or salt spray environments for a long time. Therefore, the exterior of photovoltaic connectors is usually made of corrosion-resistant materials, such as gold-plated or silver-plated contacts, or corrosion-resistant metal shells to ensure long-term stable operation.

8. Low contact resistance

When designing photovoltaic connectors, special attention is paid to low contact resistance to ensure smooth current flow, reduce heat generated by excessive resistance, avoid losses and improve system efficiency.

9. Compliance with international standards

Photovoltaic connectors usually need to comply with international standards, such as IEC 62852 (international standards for the design and testing requirements of photovoltaic connectors). In addition, some certification standards, such as UL, TUV, etc., ensure the quality and safety of connectors, especially when used in different environments in different regions of the world, in accordance with the certification requirements of various countries.

10. Adaptability and compatibility

The design of photovoltaic connectors usually takes into account the compatibility of photovoltaic panels, inverters, and battery energy storage devices of different models and brands to ensure that photovoltaic components and systems can be seamlessly connected.

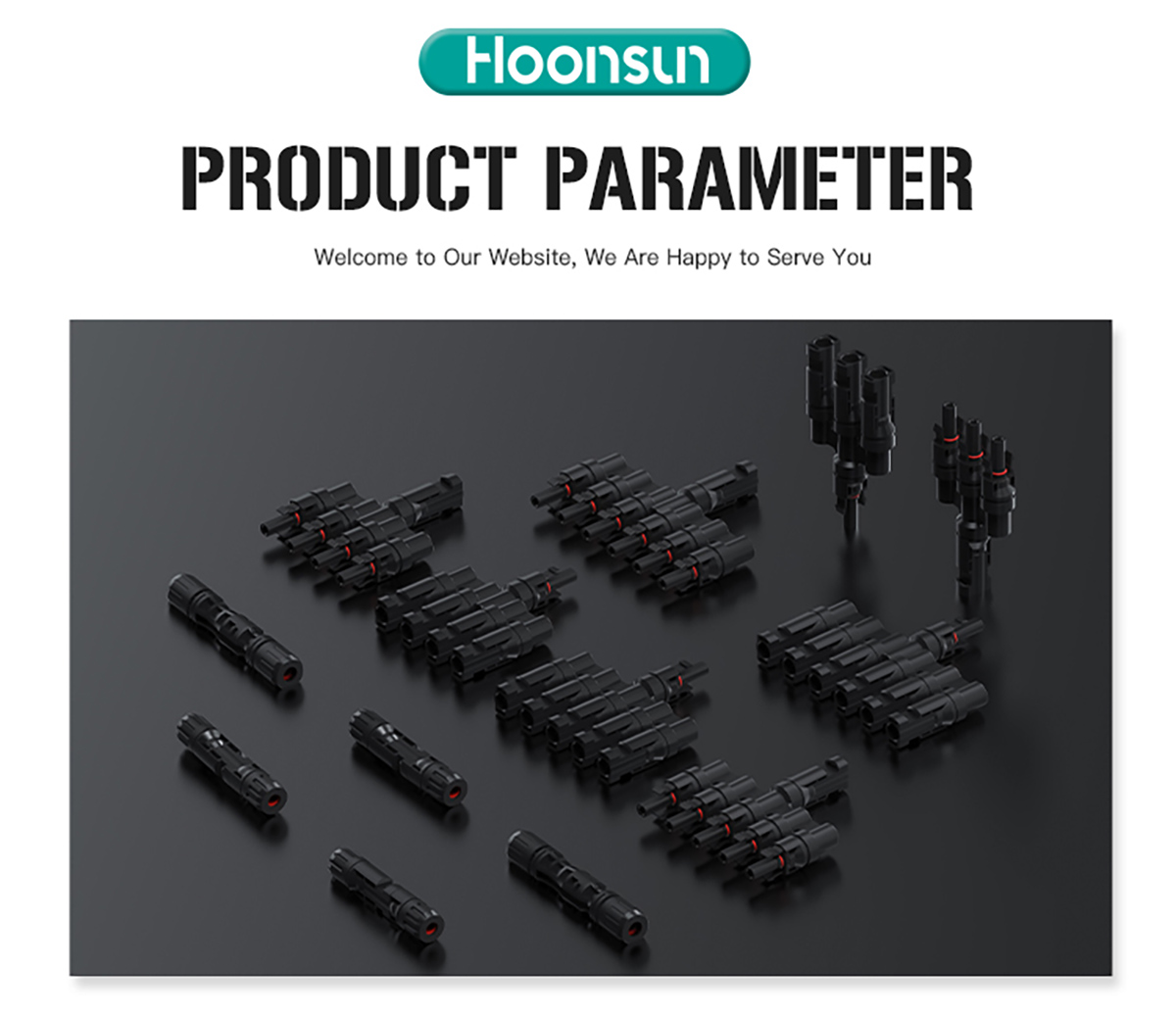

Common Solar connector type:

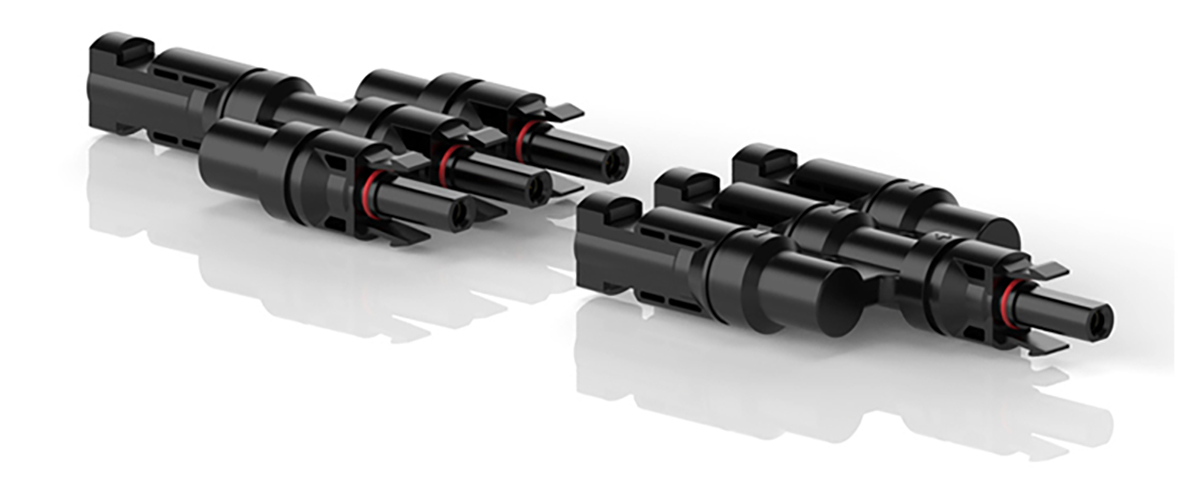

1. MC4 connector (most common type of photovoltaic connector):

MC4 connector is the most common connector in photovoltaic system, with high current carrying capacity and waterproof design. It is usually used to connect the output end of solar panels and parallel or inverter.

Its features include: easy plug and unplug, automatic locking design, arc protection, long-term UV resistance, etc.

2. T4 connector:

T4 connector is more compact than MC4 and is often used in medium-sized photovoltaic systems. Its advantages are lower installation cost and suitable for photovoltaic wiring with smaller current and shorter distance.

3. Solar Y connector:

Solar connector (or parallel connector) is used to connect the positive and negative poles of multiple solar panels to ensure the effective convergence of electricity.

4. Quick connector:

Some modern photovoltaic connectors adopt quick plug and unplug design (that is, no tool required), providing a simpler installation and removal experience.connector types:

1. MC4 connector (most common type of photovoltaic connector):

MC4 connector is the most common connector in photovoltaic system, with high current carrying capacity and waterproof design. It is usually used to connect the output end of solar panels and parallel or inverter.

Its features include: easy plug and unplug, automatic locking design, arc protection, long-term UV resistance, etc.

2. T4 connector:

T4 connector is more compact than MC4 and is often used in medium-sized photovoltaic systems. Its advantages are lower installation cost and suitable for photovoltaic wiring with smaller current and shorter distance.

3. Solar connector:

Solar connector (or parallel connector) is used to connect the positive and negative poles of multiple solar panels to ensure the effective convergence of electricity.

4. Quick connector:

Some modern photovoltaic connectors adopt a quick plug and unplug design (that is, no tool required), providing a simpler installation and removal experience.