Our cable gland has a wide range of uses, which can be used to connect the LED lamp line interface, the laying of the circuit cable, and the connection of the electric box cable.

It can also be used in the cable connection of the manufacturing industry equipment, the line connection of the robot industry, the connection of the charging pile line, and the application in new industries such as wind energy and solar energy.

The cable connector has corrosion resistance and can be applied to marine operations, chemical equipment and so on.

Product Description

Screw type: German thread PG

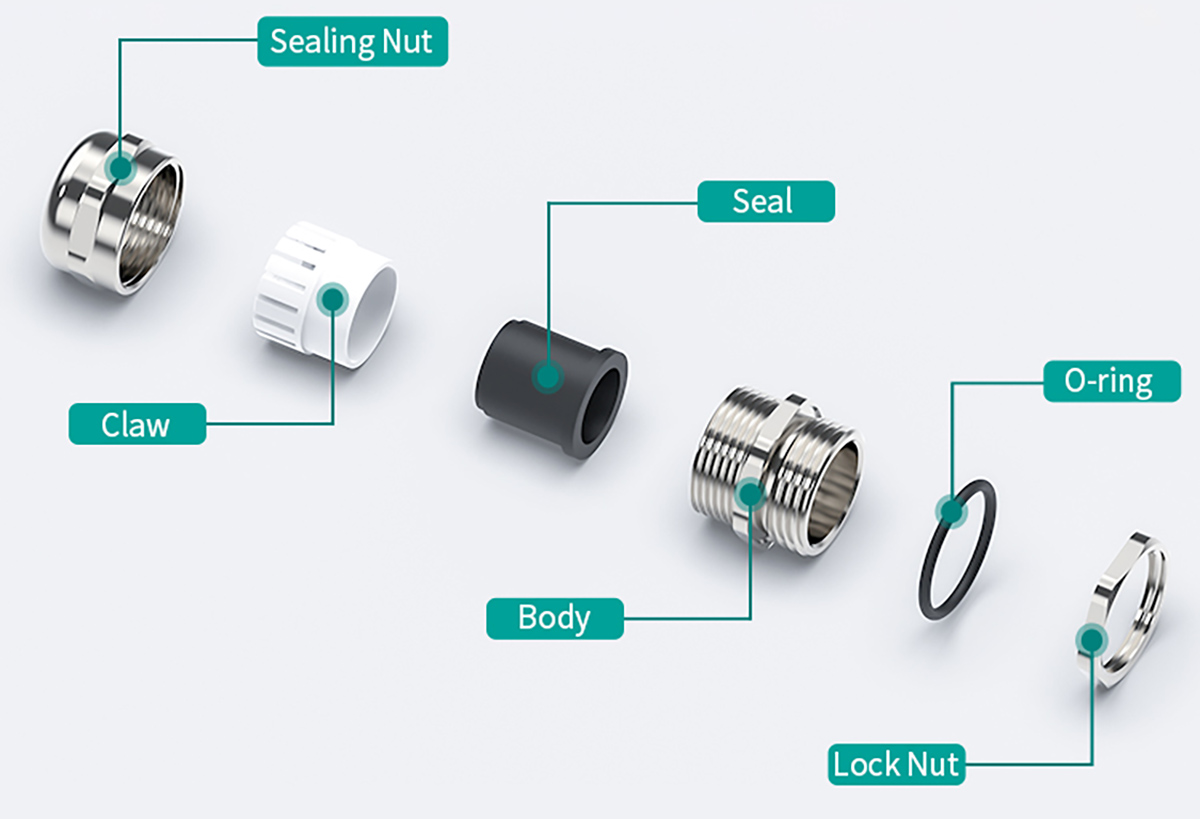

Product structure: tight nut, inner core (clamping claw, seal), main body, O-Ring and nut.

Product material: brass, nylon plastic, nitrile rubber, silicone rubber.

Surface treatment: electroplating

Waterproof grade: IP 68-10 bar Working temperature: static -40 ℃ to 100 ℃, dynamic -20 ℃ to 80 ℃.

Product performance: waterproof, dust-proof, corrosion-resistant and non-polluting.

Applicable environment: offshore operations, mine machinery, chemical equipment and other bad work.

Product Introduction

Waterproof metal cable gland type:

Large type cable gland, large range type cable gland, small range type cable gland, length type cable gland, strengthened type cable gland, direct type cable gland, multiple-entry type cable gland, high-temperature resistance type cable gland, double locking type cable gland, spiral type cable gland, 90º flexible pipe connector, EMC cable gland, and explosion proof cable gland, etc.

Nylon cable gland type:

Conventional type cable gland, split type cable gland, anti-bending cable gland, corrugated tubing cable gland, nylon union for flexible pipe, hose cable gland, etc.

Marine cable gland:

DCG single compression type cable gland, JIS standard type cable gland, TJ clamping type cable gland TH welded type cable gland, etc.

Flexible Pipe type:

PP/PA flexible pipe, metal flexible pipe, bellows fixed frame, etc.

Vent valve series:

Breathable vent plug and breathable cable gland, etc.

Accessories:

Brass reducer, brass enlarger, standard locknut, EMC locknut, brass screw plug and waterproof junction box, etc.