During cable laying, it’s often impossible to install the entire length in one go. In these cases, two sections of cable need to be connected at a cable gland. A cable gland is the connection point between two cables and is critical for both electrical performance and mechanical protection.

From the installation position, cable glands can be divided into intermediate glands (installed in the middle of the cable route) and end glands (installed at the termination of the cable). In addition to providing a reliable electrical connection, a high-quality cable gland must also offer mechanical strength, insulation performance, waterproofing, dustproofing, and vibration resistance, ensuring long-term safe and stable operation of the cable system.

What Are The Working Principle Of a Cable Gland?

Cable glands serve far more than simply “connecting two conductors.” Their primary function is to ensure that the electrical performance at the gland, including conductor connection, electric field distribution, insulation restoration, and shielding/sheath restoration, is highly consistent with the original cable structure.

By precisely reconstructing these critical elements, well-designed cable glands help maintain the overall reliability, safety, and long-term stability of the cable.

What Are the Main Cable Gland Structure Types?

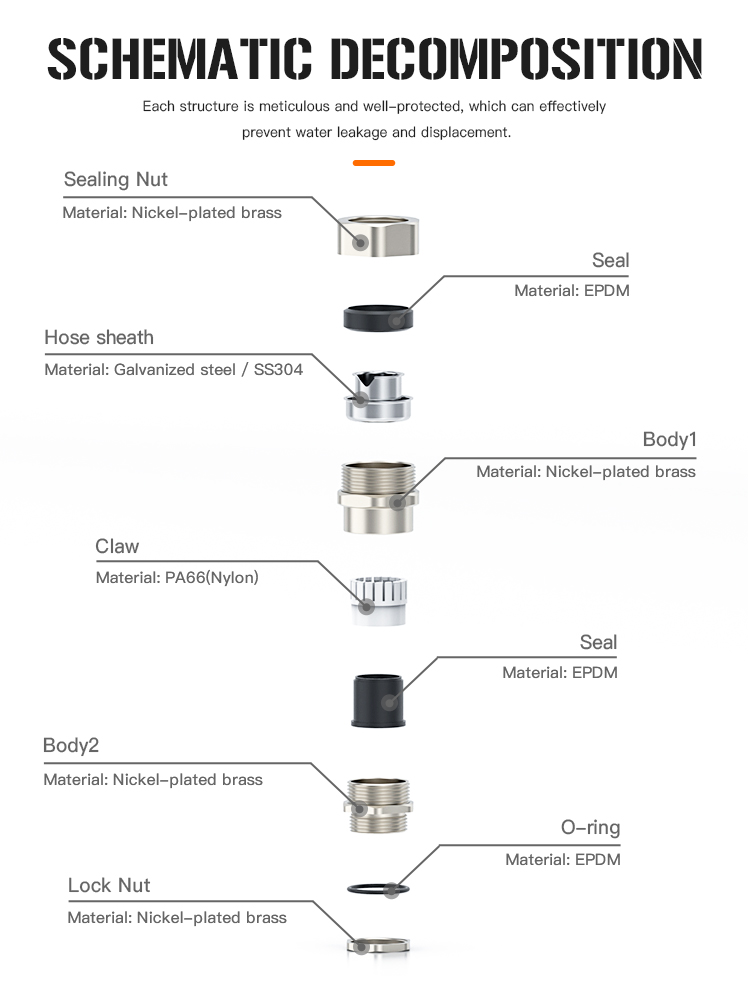

A cable gland is made up of several key structural parts. Each part plays a different role in maintaining electrical performance, mechanical strength, and environmental protection at the gland.

1. Conductor Connection

The conductors (copper or aluminum) of the two cable sections must be reliably connected to ensure:

- Low contact resistance

- Stable current-carrying capacity

- Good long-term electrical contact

- Common conductor connection methods include crimping, welding, and bolted connections.

If the contact is poor, it can cause localized overheating, increased resistance, and eventually gland failure.

2. Insulation and Electric Field Restoration

Beyond the conductor, a cable contains insulation layers, semiconductive shielding layers, metallic shielding/armor, and an outer sheath. At the gland, these structures must be reconstructed as closely as possible to the original cable design to:

- Maintain insulation performance

- Ensure uniform electric field distribution along the cable

- Poor restoration,such as air gaps, uneven insulation thickness, or discontinuous shielding.It can cause electric field concentration, leading to partial discharge, insulation aging, or even breakdown.

3. Outer Sheath, Shielding, and Armor Restoration

For high-voltage or armored cables, the metallic shielding and armor layers are crucial.

They provide:

- Mechanical protection against impact and compression

- Electromagnetic shielding reduces interference

- Grounding and fault current return paths

At the gland, these layers must be reconnected and restored to avoid additional electrical and safety risks.

The outer sheath also needs to be:

- Waterproof and dustproof

- Corrosion-resistant

- Resistant to UV, chemicals, and environmental aging

This ensures long-term reliability of the cable gland in harsh environments.

4. Mechanical Fixing and Waterproof Sealing

Cable glands usually incorporate specialised accessories or junction boxes, which may include:

- Sealing materials and waterproof gaskets

- Cable glands, heat shrink or cold shrink tubing

- Mechanical clamping and strain relief components

These structures:

- Securely fix the cable in place, preventing tension, bending, or vibration from being transmitted to the core gland

- Provide effective waterproof and dustproof sealing, blocking moisture and contaminants from entering

Improve overall mechanical stability and extend the service life of the gland