How to Use Stainless Steel Cable Glands in the Food Industry?

The food industry is one of the most demanding sectors when it comes to safety, hygiene, and reliability. With stringent regulatory requirements, ensuring that every piece of equipment used in food production adheres to the highest standards is crucial.

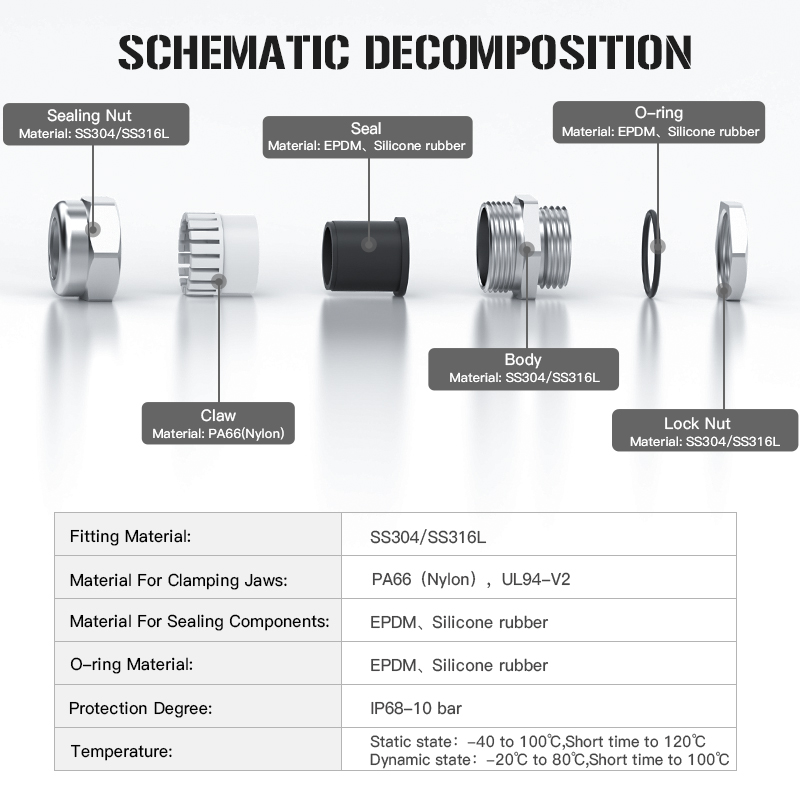

One such critical component often overlooked in food processing and manufacturing is the cable gland. Specifically, stainless steel cable glands are essential for ensuring that the wiring and electrical installations in food plants meet safety and hygiene standards while maintaining functionality in demanding environments.

This article delves into the importance of using stainless steel cable glands in the food industry, highlighting their role in preventing contamination, their hygienic design, and the various standards they meet. By the end of this guide, you will understand why stainless steel cable glands are a vital part of the modern food production line.

Why Stainless Steel Cable Glands Are Essential in the Food Industry?

In the food industry, maintaining hygiene and preventing contamination are of paramount importance. Electrical installations in food processing facilities, especially those in close proximity to food handling areas, need to meet specific hygiene standards. Stainless steel cable glands are one of the most reliable solutions for sealing cables and wires in food processing plants, helping to prevent contaminants from entering food production areas.

Key Features of Stainless Steel Cable Glands in the Food Industry

Hygienic Design

Stainless steel cable glands are specifically designed to meet strict hygiene standards. They are easy to clean and resistant to harmful substances like cleaning agents, chemicals, and water. Their smooth surface prevents the accumulation of dirt, bacteria, and food particles, making them ideal for use in food processing environments.

Corrosion Resistance

Stainless steel is highly resistant to corrosion, which is a crucial property for food industry applications. In environments where high moisture levels, cleaning agents, and corrosive chemicals are prevalent, stainless steel cable glands maintain their integrity and performance over time, ensuring that your equipment remains safe and functional.

Sealing Performance

The tightness of the seal in stainless steel cable glands is another key benefit. Proper sealing prevents the ingress of dirt, water, and other contaminants, which is critical in food manufacturing areas. This ensures that cables remain protected and free from any external elements that could compromise product safety or cause equipment failure.

Temperature and Pressure Resistance

Food processing plants often experience extreme temperatures, either from high-pressure steam cleaning processes or from cold storage conditions. Stainless steel cable glands are able to withstand these temperature extremes, ensuring that electrical components remain protected and function optimally, even in challenging environments.

Durability and Longevity

Stainless steel is an exceptionally durable material. It is resistant to wear and tear, even in harsh industrial environments. Food production facilities that rely on equipment that is frequently exposed to heavy use and demanding conditions will benefit from the longevity of stainless steel cable glands, reducing the need for frequent replacements.

Standards and Certifications for Stainless Steel Cable Glands

Stainless steel cable glands used in food manufacturing must meet stringent hygiene and safety standards. Some of the key certifications and standards that these cable glands adhere to include:

EN 60423:2007: Conduits for electrical purposes – Outside diameters of conduits for electrical installations and threads for conduits and fittings

EN 60423:2007

Specifies the following key parameters:

Conduit Nominal Size:

The standard defines a series of nominal sizes (e.g., 16, 20, 25, 32, 40, 50, 63, etc.). This number approximates the outer diameter of the conduit, expressed in millimeters (mm). This serves as the basis for selecting conduit and fittings.

Conduit Outside Diameter:

The standard specifies precise outside diameter tolerances for each nominal size. This is the core of standardization, ensuring that conduits from different brands can be installed in the same size.

Standardized Fit:

By standardizing the outside diameter and thread, a nominal size 20 conduit will fit perfectly into any connector, box, or locknut marked with the same size 20 from any manufacturer.

EN ISO 6149-1:2022 – Connections for hydraulic fluid power and general use – Ports and stud ends with ISO 261 metric threads and O-ring seals – Part 1: Ports with elastomeric or metal-to-metal seals

1. Key Features

Metric Threads: Uses metric fine-pitch threads conforming to ISO 261 (e.g., M12x1.5, M16x1.5, M18x1.5, M22x1.5, etc.). This fundamentally differs from the other mainstream standard, SAE J514, which uses imperial UN/UNF threads.

O-Ring Seal: The core sealing method utilizes an O-ring at the root of the thread to create a face seal. This sealing method is highly reliable, capable of withstanding high pressures and exhibiting excellent vibration resistance.

Applications: Primarily used in hydraulic systems, but also widely used in other fluid transmission systems (such as lubrication and cooling systems) and pneumatic systems (especially high-pressure pneumatics) requiring reliable sealing.

Benefits of Using Stainless Steel Cable Glands in Food Production

Prevention of Product Contamination: Stainless steel cable glands are designed to provide a sealed environment that protects food production from contamination. They ensure that cables and electrical connections are not a source of contamination, which is essential in maintaining the integrity of food products. Contamination risks are minimized, which helps food manufacturers comply with safety regulations and avoid costly product recalls.

Long-Term Reliability: With their resistance to corrosion and their robust construction, stainless steel cable glands provide long-term reliability in food processing applications. These glands are built to last, even under harsh conditions, which means less maintenance and fewer production downtimes. Manufacturers benefit from fewer interruptions to their production lines, increasing overall efficiency.

Improved Cleaning Efficiency: The smooth surface and tight seals of stainless steel cable glands make them easy to clean. In the food industry, regular and effective cleaning is essential to prevent contamination. The ease of cleaning reduces the overall cleaning time and ensures compliance with hygiene standards. Quick and effective cleaning processes reduce labor costs and ensure the food production area remains sanitized.

Reduced Total Cost of Ownership (TCO): Although stainless steel cable glands may have a higher initial cost compared to other materials, their long-term durability, resistance to wear and tear, and reduced maintenance costs lead to a lower total cost of ownership. Investing in high-quality, durable components means fewer replacements and maintenance interventions in the future. Additionally, their long service life contributes to higher operational efficiency and reduces operational costs.

Safety and Compliance: Using stainless steel cable glands ensures compliance with safety regulations. Given that the food industry is heavily regulated, manufacturers are required to adhere to strict safety standards. Stainless steel cable glands offer peace of mind, as they are designed and certified to meet or exceed the required safety criteria, including electrical safety and hygiene standards.

Applications of Stainless Steel Cable Glands in the Food Industry

Stainless steel cable glands are widely used in various parts of the food industry, particularly in environments where hygiene and safety are critical. Some common applications include:

Food Processing Plants: Stainless steel cable glands are used in food processing machinery, where they prevent contamination and ensure safe electrical connections in high-hygiene zones. This includes areas such as production lines, packaging machinery, and mixing equipment.

Packaging Equipment: Food packaging lines require electrical installations that are both reliable and hygienic. Stainless steel cable glands are used to seal cables in automated packaging equipment, ensuring that the equipment remains clean and safe to operate.

Beverage Production: Beverage manufacturers, including those producing juices, soft drinks, and alcohol, rely on stainless steel cable glands to maintain clean and safe electrical installations in their production lines. Stainless steel is ideal for these applications due to its corrosion resistance and ability to withstand the harsh cleaning processes often required in beverage production.

Cold Storage and Refrigeration: In cold storage and refrigeration units, cable glands are used to seal electrical cables and prevent moisture ingress, which could damage equipment or compromise safety. These glands ensure that the electrical components remain functional, even in extreme temperatures.

Cleaning Systems: Stainless steel cable glands are also used in the cleaning systems of food plants. These systems must be able to withstand high-pressure water jets, cleaning chemicals, and extreme temperatures. Stainless steel cable glands are designed to endure these harsh conditions, ensuring the systems remain operational and contamination-free.

Conclusion

In the food industry, stainless steel cable glands play a crucial role in ensuring that electrical installations are safe, reliable, and hygienic. With their resistance to corrosion, ability to provide tight seals, and compliance with stringent hygiene standards, stainless steel cable glands help to prevent contamination and ensure the smooth operation of food production lines.

By investing in high-quality, hygienic cable glands, food manufacturers can achieve greater reliability, reduce downtime, and minimize the risk of product recalls or contamination. The long-term benefits, including improved cleaning efficiency, reduced maintenance, and a lower total cost of ownership, make stainless steel cable glands an essential component in food industry applications.